This Part 3/3 of this Article is a continuation of Part 1/3 and 2/3, published previously.

Indirect cable entries into “Ex” metal enclosures with “explosion-proof” (Ex “db”) types of protection with “increased safety” (Ex “eb”) junction boxes, with combined Ex “db eb IIC Gb” protections provide, among others, the benefits of increased “Ex” field service facilities for the assembly, inspection and maintenance activities of automation, telecommunication and electrical equipment and installations in hazardous areas containing flammable gases.

As it could be verified in Part 1/3 of this Article, the system of DIRECT cable entries inside metal enclosures with type of Ex “d” protection can present undue “deviations”, resulting from failures of “Ex” field services, related to failures of “Ex” design, assembly, inspection and maintenance services in hazardous areas.

In Part 2/3 of this Article, the characteristics of indirect cable entries in Ex “d” metallic enclosures, by means of Ex “d” “bushings” and by means of use of external terminal box, with type of protection Ex “e” (increased safety) were shown, as well as the benefits obtained, from the point of view of easy assembly, inspection and maintenance “Ex”, and from the point of view of safety of the instrumentation, automation, telecommunications and electrical installations in hazardous areas, resulting from the use of the system of INDIRECT cable entries, in relation to the system of DIRECT cable entries to the interior of metal enclosures of equipment with type of protection Ex “d” (“explosion-proof”).

This Part 3/3 of this Article shows suitable examples of equipment installations incorporating the appropriate COMBINATION of the Ex “db” and Ex “eb” protection types, using the system of INDIRECT cable entries through the use of Ex “d” bushings and “increased safety” (Ex “eb”) terminal boxes.

The following are some practical examples of “Ex” equipment installations containing “explosion-proof” (Ex “d”) type metallic enclosures, where the external cable entries into the interior of the Ex “d” metallic enclosure are not made “directly”, for example by means of Ex “d” cable glands or Ex “d” sealing units, but in an “INDIRECT” way, through a terminal box with type of protection “increased safety” (Ex “e”), dispensing with the need for additional field installation of Ex “d” type installation components and accessories, such as cable glands, sealing units, nipples or male/female couplings of the “explosion-proof” type.

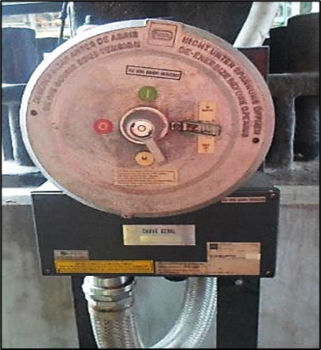

Example of “Ex” equipment installation incorporating the combination of Ex “db” and Ex “eb” protection types, comprising metal Ex “db” explosion-proof enclosure (internally containing sparking components) and “increased safety” type terminal box (Ex “eb”), with an INDIRECT cable entry system through sealed cable (bushing)s. Complete “Ex” equipment, certified for installation in explosive atmospheres, with Ex db eb IIC T5 Gb marking

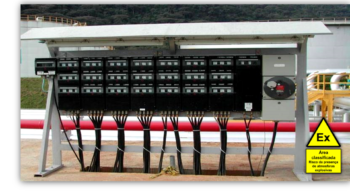

Example of Ex “db eb IIC Gb” distribution switchgear for power and control circuits, with metal enclosure of the “explosion-proof” type (internally containing sparking components), with THREADED cover and INDIRECT cable entry system by sealed cable (bushings). Full markings: Ex db eb IIC T4 Gb / Ex tb IIIC T135 ºC Db

Example of Ex “db eb IIC Gb” distribution switchgear for power and control circuits, with the presence of a single metal enclosure of the “explosion-proof” type (internally containing sparking components), with a THREADED cover and a system of INDIRECT cable entries through sealed (bushings). On the left side can be seen power circuit distribution panels, with plastic enclosures, internally containing individually certified spark gaps (circuit breakers and contactors) (Ex db eb IIC Gb U). Panels with complete markings: Ex db eb IIC T4 Gb / Ex tb IIIC T135 ºC Db

Installation example (on the left side) of “Ex” equipment incorporating the combination of Ex “db” and Ex “eb” protection types, consisting of metal Ex “db” explosion-proof enclosure (internally containing sparking components) and of “increased safety” type terminal box (Ex “eb”), with an INDIRECT cable entry system through sealed cable (bushings). On the right side can be seen a switchgear for power circuits with plastic casing, internally containing individually certified (Ex db eb IIC Gb U) spark gaps (circuit breakers and contactors). Complete “Ex” equipment certified for installation in explosive atmospheres, with markings Ex db eb IIC T5 Gb / Ex tb IIIC T100ºC Db

Example of an Ex “db eb IIC Gb” distribution switchgear for power circuits, with the presence of a single metal enclosure of the “explosion-proof” type (internally containing sparking components), with a THREADED cover and a system of INDIRECT cable entries through sealed bushings. On the left side you can see several switchgear panels for power circuits, with plastic casings, internally containing individually certified spark gaps (circuit breakers and contactors) (Ex db eb IIC Gb U). Complete panel with markings: Ex db eb IIC T5 Gb / Ex tb IIIC T100°C Db

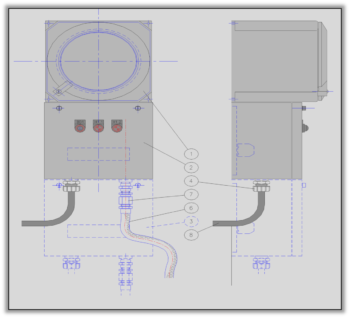

Example of a TYPICAL DESIGN DETAIL for standardization of technical specification and assembly of “Ex” distribution switchgear for power and control circuits, with metal enclosure of the “explosion-proof” protection type. Example of markings: Ex db eb IIC T4 Gb / Ex tb IIIC T135 ºC Db. Ex “d” metallic enclosure with THREADED cover and INDIRECT cable entry system through sealed (bushings), by means of “increased safety” type terminal box (Ex “eb”)

Example of “Ex” switchgear assembly for power and control circuit distribution, with metal enclosure with protection type Ex “db eb” or Ex “t”. THREADED cover and INDIRECT cable entry system through sealed (bushings) by means of terminal box type “increased safety” (Ex “eb”). Example of full markings: Ex db eb IIC T4 Gb / Ex tb IIIC T135 ºC Db

Considerations on the benefits of INDIRECT cable entries into equipment with “explosion-proof” type metal enclosures – Combined Ex “db eb IIC Gb” protections

[1] One of the ways to simplify the field service requirements in “Ex” assembly, inspection and maintenance is the use of metal Ex “d” enclosures with threaded covers and a system of INDIRECT cable entries into the interior of the enclosure by means of terminal boxes with increased safety type protection (Ex “e”), supplied by the manufacturers themselves together with the Ex “d” equipment”

[2] The use of sealed cable (bushings) of the Ex “d” type, together with terminal boxes of the increased safety type (Ex “e”) makes it possible for manufacturers to make available on the market equipment with metal enclosures with the combined protection types Ex “db and eb”, with a system of INDIRECT cable entries into the interior of the metal enclosure Ex “d”, providing benefits and superior technical characteristics in relation to the equipments with direct entries system, in terms of bigger facilities of assembly services, inspection and field “Ex” maintenance, in hazardous areas, from the point of view of facilities for users and owners of equipment and installations in explosive atmospheres

[3] Equipment with Ex “d” metal enclosures with an INDIRECT cable entry system by means of Ex “eb” junction boxes, incorporating the combination of the Ex “db eb Gb” protection types present more simplified field service characteristics, when compared with equipment with Ex “d” metal enclosures with a direct cable entry system, either by means of Ex “d” cable glands or by means of Ex “d” sealing units for conduits

[4] All types of “Ex” protection can be considered “safe“, but only if the respective “Ex” instrumentation, automation, telecommunications, electrical or mechanical equipment has been properly specified, selected, installed, inspected, maintained or repaired, throughout its total life cycle. For these reasons “Ex” equipment should be specified which provides simpler field services from the point of view of the users and owners of the “Ex” equipment, who are responsible for the safety of their installations

[5] In eventual cases, when there are no technical alternatives for the specification of equipment with metallic “explosion-proof” type enclosures, Ex “d” enclosures with THREADED lids and with an INDIRECT input system can be specified. In this kind of “Ex” products, available in the market since the 1970’s, the cables external to the “Ex” equipment (power, command or automation circuit cables), installed by the users or owners of the equipment and installations, are connected to terminal boxes of the increased safety type (Ex “e”), not needing the opening of the metallic explosion-proof enclosures, reducing the risk of human errors in the field services for assembly, inspection or maintenance. Furthermore, the Ex “d” metal enclosures with threaded covers, dispense the need of installing a large quantity of screws, as in the case of fixing the covers by means of flanged joints

[6] The use of metallic Ex “d” type “explosion-proof” enclosures shall be restricted to cases where they are actually necessary, for example, in particular cases where it is necessary to install, in hazardous areas, sparking electrical components, such as contactors, power circuit breakers and circuit breakers with capacities above 250 A / 25 kA

[7] Equipment with metallic enclosures of the Ex “d” type with an INDIRECT entry system for its interior of power, control or automation cables, including copper or optical fiber cables, present, among others, the benefits of DISPENSING the need of installation of “Ex installation accessories”, such as, sealing units for Ex “d” conduits or Ex “d” cable glands, contributing for the reduction of occurrence of eventual and undue “deviations” or “non conformities” of field “Ex” installation or maintenance services, also contributing for the elevation of safety levels and normative conformity in hazardous areas of terrestrial and maritime installations

Roberval Bulgarelli

Technical Consultant on equipment and facilities in explosive atmospheres

Electrical Engineer, with Master’s degree in protection of power electrical systems (POLI/USP)

Book Organizer of the “The total life cycle of facilities in explosive atmospheres”