Synopsis: “Ex” instrumentation, automation, telecommunications, and electrical components and equipment can be manufactured with plastic or metal enclosures with the Ex “d” type of protection (flame-proof), being suitable for installation in classified areas containing flammable gases Zone 1 or Zone 2.

Equipment or components with “flame-proof“ (Ex “d“) type enclosures are those in which the internal sparking parts that can cause ignition of an explosive atmosphere of flammable gases are confined inside an enclosure that is able to withstand the pressure developed during an internal explosion of an explosive mixture, and that also prevents the propagation of this internal explosion to the external explosive gas atmosphere, existing around the Ex “d“ equipment, which could cause a catastrophic accident in installations containing classified areas. In the Ex “d” type of protection explosions are not prevented and must consequently be contained.

In 1921 the Department of Mines at the University of Sheffield, in the UK, started research work on “flame-proof” equipment in collaboration with the SMRB (Safety in Mines Research Board) and the British Electrical and Related Industry Research Association, later called the ERA (Electrical Research Association). In 1922 the University of Sheffield, began to carry out “commercial” tests of explosion-proof equipment for some individual manufacturers, when the first certificate was issued by that University.

The first electrical equipment that was used in coal mines was due to the advent of motors with “flame-proof” type metal enclosures to drive elevators, fans, and mining equipment. Coal mine operators observed at that time, however, that other electrical equipment besides motors could also be used inside enclosures with “reinforced flame-proof” type walls and joints, such as fuses, light fixtures, and plugs.

In Brazil, equipment with metal enclosures of the “explosion-proof” type were initially used in the construction of the first oil refineries, starting in the 1930s, with the installation of the first oil refinery in Rio Grande do Sul State, at the Southern part of the Country. Due to the influences of the North American Electrical Code (NEC) and the North American design and construction companies, a “culture” of using “explosion-proof” type metallic equipment with flanged covers fixed by bolts was created in Brazil, from the 1930s and 1940s, among national manufacturers of electrical equipment for classified areas.

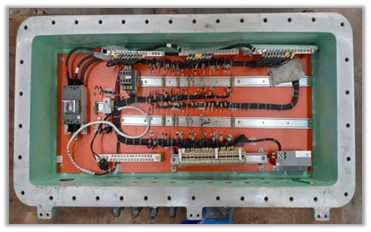

The following figure shows an example of an internal view of an Ex “d” enclosure with flanged joint and screwed cover (equipment seen without the cover), in which the large “empty internal volume” existing inside the equipment can be verified. It also can be seen the large number of holes for fixing the cover with screws, necessary to withstand the pressure resulting from an internal explosion.

Electrical and instrumentation equipment of the “flame-proof” type needs to have much more “reinforced” or “robust” metal enclosures than electrical or instrumentation products for “ordinary industrial” use, in order to withstand the pressure of an internal explosion, without being damaged and without allowing this internal explosion to propagate outwards. A luminaire, for example, that only has the “flame-proof” type of protection for the manufacture of its complete enclosure, has a higher weight and more “complex” assembly and “Ex” maintenance procedures when compared to an “ordinary” industrial luminaire.

Furthermore, the requirements for installation, inspection, maintenance, repair, and reclamation procedures for a luminaire with “explosion-proof” type metal enclosure are more complex and stringent compared to a “common” industrial luminaire or even one manufactured with other types of combined “Ex” protection, such as Ex “eb mb IIC” or Ex “ec mc IIC”. The same applies to other types of “Ex” electrical or instrumentation equipment, such as Junction Boxes, which have no sparking components inside.

One of the “conceptual” characteristics in these types of “flame-proof” metal enclosures is the existence of large internal void volumes between the devices installed inside. These large “internal void volumes” allow the accumulation of large quantities of explosive atmospheres inside the Ex “d” enclosure, coming, for example, from the external vicinity where the equipment is installed. This large quantity of explosive atmosphere, in turn, gives rise to a large explosion inside the enclosure when it comes into contact with the sparking parts of the components that are installed inside.

This great pressure resulting from the internal explosion, with the generation of great energy, needs to be “contained” by means of enclosures that have thick walls, otherwise the enclosure would be destroyed by the internal explosion. In addition, there is the need to install a large number of screws to fix the cover, otherwise the cover would be “torn” from the enclosure, or it would allow the creation of “interstices”, or “gaps” that would cause the internal explosion to unduly propagate to the outside of the enclosure, putting the entire plant at risk of a catastrophic explosion. For reasons of safety and more rigorous enclosure design, the Ex “d” metal enclosures are tested “empty” in the laboratories, making the internal volume as large as possible, leading to the need for greater wall thicknesses and a greater number of fastening bolts for the covers.

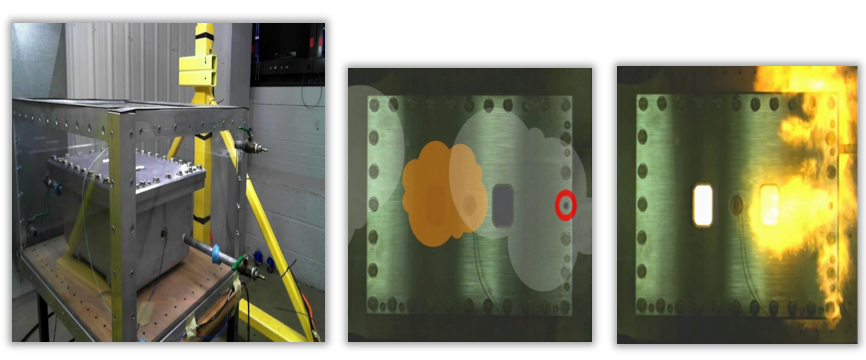

Manufacturers of “Ex” equipment with “flame-proof” type metal enclosures with flanged covers fixed by several bolts are themselves concerned about the safety that this equipment may or may not provide when installed in classified areas and warn the owners of this type of Ex “d” equipment about the possibilities of propagation of primary explosions (which may occur inside the Ex “d” enclosure) resulting in secondary explosions (which may occur outside, around the Ex “d” enclosure), with the possible “devastating” or catastrophic consequences that can occur, arising from these undue propagations.

According to one of the world’s largest manufacturers of “Ex” equipment, this type of risk situation, which can occur in cases where only a single one of several screws securing the covers to the Ex “d” enclosures is missing or improperly tightened, can be verified in the instructional video “An important safety message from Eaton Crouse Hounds Business: Understanding explosion proof NEMA 7 enclosures”, available at: https://www.youtube.com/watch?v=nccrAqNUPbs

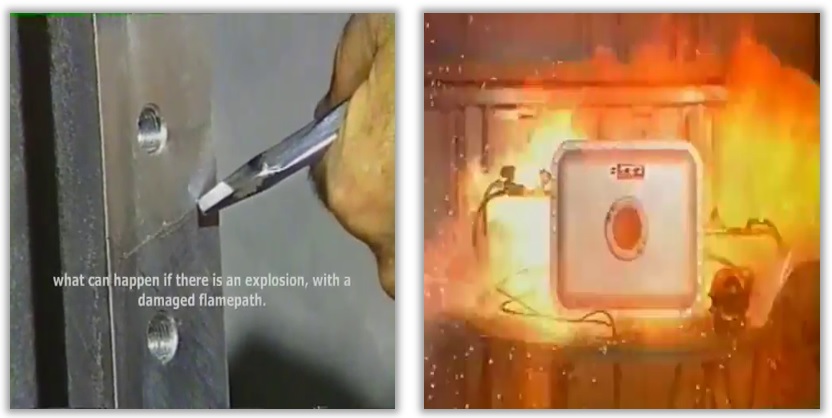

Other problems related to metal “flame-proof” type enclosures with flanged covers fixed by several bolts are related to the existence of mechanical damage that can occur on the flange faces that represent “flame passage” areas. In cases where these flanged faces may be damaged, caused for example by improper mechanical impacts from hand tools, an internal explosion may be improperly propagated to the external side of the “flame-proof” equipment, compromising the safety of the installations in classified areas, and may cause “devastating” or catastrophic effects, according to the video of the mentioned equipment manufacturer “Ex” metal enclosures (flame proof) Ex “d”.

.

An educational video on this subject shows the possible “consequences” of equipment with Ex “d” metal enclosures having improperly mechanically damaged flanged joints: https://www.youtube.com/watch?v=MTP1FGZFPKU

Individually certified components with the “explosion-proof” type of protection

As technical alternatives of manufacturing equipment with type of “Ex” protection to dispense with the need to install Ex “d” metal enclosures with flanged joints and screwed covers can be mentioned the installation of sparking devices inside pressurized enclosures (Type of protection Ex “p”), as in the cases of local control panels installed in classified areas.

There is also available in the market, since the decade of 1990, sparking components installed inside a plastic flame-proof enclosure (Ex “db”), with increased safety terminals (Ex “eb”), with COMBINED protections Ex “db eb IIC” (U). Using this manufacturing technique, the available empty spaces to be occupied by flammable gases inside the plastic casing are reduced, making it able to withstand the pressure of an internal explosion, without allowing this explosion to propagate to the external environment.

The following Figure shows a sectional view of an example of a spark gap component (circuit breaker) mounted inside Ex “d” (explosion-proof) enclosure, with terminals and plastic enclosure with Ex “e” (increased safety) type of protection. Ex marking of IIC Gb, with certification with suffix “U” (“Ex” component).

These Ex “db eb” components can be installed inside increased safety enclosures (Ex “e”), with external enclosures made of thermoplastic material or aluminum or stainless-steel plates. This type of Ex “db eb” IIC Gb (U) spark gap components has, among others, the benefits of dispensing with the need for an outer metallic enclosure of the “flame-proof” type, also dispensing with the need for the installation of Ex “d” conduit fittings, such as Ex “d” conduit sealing units, nipples, and male/female couplings.

These combinations of type of Ex db eb IIC Gb” protections (or Ex “eb mb IIC Gb”) represent significant technological solutions of the market in terms of greater easiness of assembly, inspection, and maintenance “Ex” field services in classified areas, contributing to reduce the occurrence of eventual “deviations”, increasing the safety levels in instrumentation, automation, telecommunications, and electrical installations in explosive atmospheres.

Examples of “Ex” equipment incorporating combined “Ex” protection types are “Ex control and automation panels and “Ex” local control panels “, containing individually certified components with combined Ex “db eb” IIC Gb (U) protection, in which the sparkling parts of electrical components (U marking), as control buttons, electrical contacts, control switches, power disconnect switches, contactors, relays or LED indicators are individually “encapsulated” in small plastic enclosures of the “flame-proof” type (Ex “db”), with terminals of the increased safety type (Ex “eb”).

Continue in next issue

Roberval Bulgarelli

Technical Consultant on equipment and installation in explosive atmospheres

Master in Protection of Power Electric Systems

Member of Working Groups of Brazilian TC 31 Mirror Subcommittee SCB 003:031 (Explosive Atmospheres) of ABNT/CB-003 (Electricity)

Member of Working Groups TC 31 (Equipment for explosive atmospheres), TC 95 (Protective Relays) and IECEx (International “Ex” Certification Systems) of IEC

Organizer of the Book “The total life cycle of installations in explosive atmospheres”